Product Description:

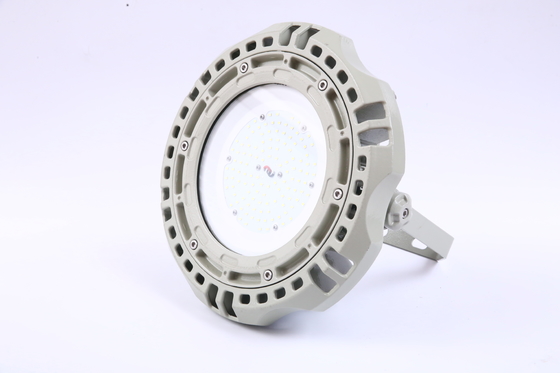

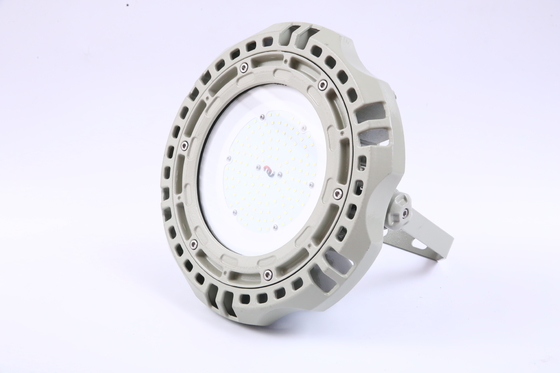

The Explosion Proof LED High Bay Lights are a top-of-the-line lighting solution designed for industrial and hazardous environments. These high bay lights are specifically engineered to provide a safe and efficient lighting option for areas where flammable gases or vapors may be present, making them ideal for use in locations such as oil refineries, chemical plants, and other potentially hazardous settings.

Featuring a color temperature range of 3000-5700K, these high bay lights offer a versatile lighting solution that can be adjusted to suit different preferences and requirements. The lamp beads used in these fixtures are sourced from CREE, a trusted name in the lighting industry known for its high-quality and durable products.

One of the standout features of the Explosion Proof LED High Bay Lights is the customizable color option, allowing users to tailor the lighting to their specific needs and aesthetic preferences. This flexibility ensures that the high bay lights can seamlessly integrate into any industrial or commercial setting, providing both functionality and style.

When it comes to power requirements, these high bay lights are designed to operate within an input voltage range of AC100~277V, with a frequency of 50Hz/60Hz. Additionally, they can also be powered by 24VDC or 36VDC, offering users multiple options for powering the fixtures based on their infrastructure and setup.

The driver used in these high bay lights is from MEANWELL, a leading manufacturer of power supply solutions known for their reliability and performance. The MEANWELL driver ensures stable and efficient operation of the lights, helping to maximize their lifespan and overall performance.

Overall, the Explosion Proof LED High Bay Lights are a must-have lighting solution for industrial and hazardous environments, offering a combination of safety, efficiency, and reliability. Whether you need an explosion proof high bay fixture, an explosion proof high bay, or a flameproof high bay light, these fixtures are sure to meet and exceed your expectations.

Features:

- Product Name: Ex Flameproof High Bay Lamp

- Application: Div 1,2 And 21, 22

- Color: Customizable

- Color Temperature: 3000-5700K

- Input Voltage: AC100~277V,50Hz/ 60Hz,24/ 36VDC

Technical Parameters:

| Input Voltage |

AC100~277V,50Hz/ 60Hz,24/ 36VDC |

| Application |

Div 1,2 And 21, 22 |

| Efficiency |

160lm/w |

| CRI |

Ra≥80 |

| Explosion Proof Grade |

Ex Db Eb IIC T6 Gb,Ex Tb IIIC T80°C Db IP66 |

| Housing Material |

Aluminium |

| Product Name |

Ex Flameproof High Bay Lamp |

| Installation |

Bracket Mount, Ceiling Mount, Flange Mount, Wall Mount |

| Driver |

MEANWELL |

| Color |

Customizable |

Applications:

1. Grain and Food Processing Industry

This is an often overlooked but extremely high-risk sector.

Grain Processing: Flour mills, sugar mills, starch mills, feed processing plants, granaries, etc. When airborne grain dust (such as flour, powdered sugar, and starch) reaches a certain concentration, it can cause a violent dust explosion upon contact with an ignition source.

Food Processing: Cooking oil production plants, alcohol breweries, etc.

2. Textile and Wood Processing Industry

Textile mills: The processing of fibers such as cotton, linen, and wool produces large amounts of flammable fiber fluff and dust.

Wood Processing: Sawmills, furniture factories, and paper mills generate combustible wood dust.

3. Other Potentially Hazardous Environments

Sewage Treatment Plants: Sewage tanks, pumping stations, and other areas may produce flammable and toxic gases such as methane (biogas) and hydrogen sulfide.

Automotive Paint Shops: Paint booths are filled with flammable paint solvent vapors.

Storage and Logistics: Warehouses, ports, and docks storing flammable materials such as paint, alcohol, and solvents.

Laboratories: Chemical and biological laboratories handling flammable and explosive chemicals.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!