Product Description:

The Explosion-Proof Switch is a high-end electrical component engineered to deliver safety and reliable performance in hazardous environments. Compatible with cables ranging from 9mm to 14mm in diameter, it meets the demands of diverse industrial applications where secure electrical connectivity is essential.

Constructed with a robust die-cast aluminum housing, the switch offers exceptional resistance to physical impact and ensures long-term functionality under challenging conditions. Its rugged design makes it well-suited for use in Zone 1 and Zone 2 hazardous areas, where explosive atmospheres may occur.

Rated with a WF1 fireproof certification, the switch provides superior fire resistance, making it ideal for safety-critical applications. Additionally, its dustproof features enhance durability and allow consistent operation even in dusty settings.

Whether used to control explosion-proof exit lights, monitor alarm signals, or activate emergency lighting systems, this switch offers a safe and dependable solution for various electrical control needs. Its versatile design and high-quality construction make it an essential component in industrial settings where operational safety and reliability are top priorities.

Features:

- Product Name: Explosion Proof Switch

- Cable Spec: 9mm-14mm

- Rated Voltage: 220VAC,380vac

- Ip Grade: IP54

- Dustproof: Yes

- Fireproof Grade: WF1

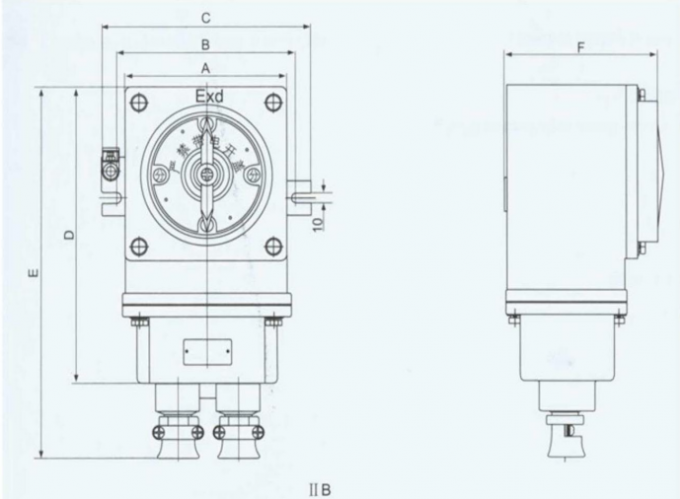

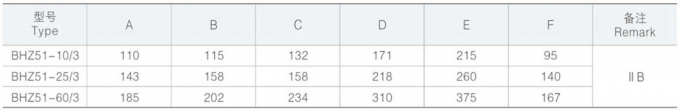

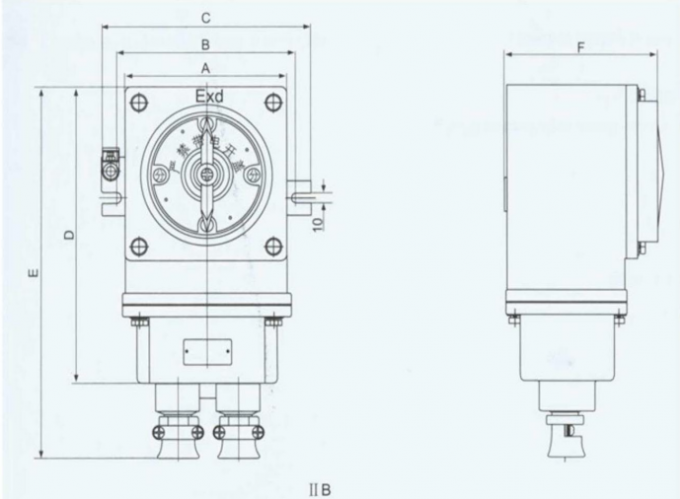

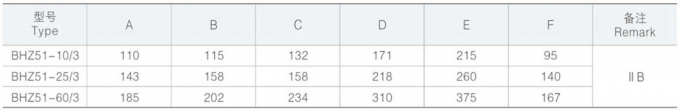

Technical Parameters:

| Product Category | Explosion Proof Switch |

| Mounting Style | Surface Mount |

| Type | Explosion Proof Switch |

| Operation | Manual switch, no warm-up required |

| Exterior | Stainless Steel |

| Ip Grade | IP54 |

| Product Name | Explosion-Proof Wall Mount BHZ51 Switch for Hazardous Areas — Aluminum Housing & Stainless Steel Exterior |

| Ex Marking | Ex Db IIC T6 Gb,Ex Tb IIIC T80°C Db |

| Application | Hazardous Locations, Oil And Gas Industry |

| Number Of Poles | 3 |

Applications:

1. Grain and Agricultural Product Processing and Storage

Sites: Grain silos, grain elevators, flour mills, sugar mills, cocoa processing plants, coffee processing plants, and feed mills.

Risks: Large amounts of combustible dust, such as flour, starch, powdered sugar, and milk powder, are generated during processing, transportation, and storage. When these fine dusts reach a certain concentration in the air and encounter an ignition source, they can cause a violent dust explosion.

2. Metal Processing and Manufacturing

Sites: Polishing, grinding, and processing workshops for metals such as aluminum, magnesium, titanium, and zirconium; and 3D printing (metal powder) workshops.

Risks: Some metals are highly flammable in powder form, especially aluminum and magnesium powders. Once they form clouds in the air, they can easily ignite and cause a violent explosion.

3. Textile and Wood Processing

Sites: Textile mills (especially those processing fibers such as cotton and linen), man-made fiber mills, wood processing plants, sawmills, and furniture manufacturing workshops.

Risks: Natural fiber dust, man-made fiber dust, and wood dust are all combustible. Accumulating to a certain concentration in a confined space can cause explosions when exposed to a fire source.

4. Municipal and Public Utilities

Sites:

Wastewater treatment plants/biogas plants: The treatment process produces flammable and explosive gases such as methane (biogas) and hydrogen sulfide.

Gas pressure regulating stations/boiler rooms: There is a risk of leakage of fuels such as natural gas and liquefied petroleum gas.

City gas pipeline wells and underground utility corridors: Leaked gas may accumulate.

Landfills/incineration plants: The decomposition of waste produces methane.

The Importance of Using Explosion-Proof Products:

Explosion-proof products (such as explosion-proof lamps, explosion-proof control boxes, and explosion-proof cables) are core equipment for ensuring industrial safety, especially in high-risk industries such as the petroleum, chemical, mining, and pharmaceutical industries. Their importance is primarily reflected in the following aspects:

1. Preventing Explosions and Ensuring Personnel Safety

Flammable and Explosive Environments Contain High Risks: Oil, natural gas, and dust, when exposed to sparks or high temperatures, can easily cause explosions.

The Function of Explosion-Proof Products: Through specialized designs (such as flameproof enclosures and intrinsically safe circuits), they prevent internal sparks or high temperatures from igniting hazardous gases/dust.

Reducing Casualties: Preventing worker injuries and deaths from explosions and complying with occupational health and safety regulations (such as OSHA and GB 3836).

Case Study: A chemical plant failed to use explosion-proof lighting, resulting in a methane explosion caused by a short circuit in conventional lighting, resulting in significant casualties.

2. Protecting Critical Equipment and Minimizing Economic Losses

Industrial equipment is expensive: Oil platforms, refineries, coal mines, and other facilities are highly valuable, and explosions can result in tens of millions in losses. Explosion-proof products: Prevent damage to equipment caused by sparks, arcs, or overheating, extending its service life.

Reduce the risk of production downtime: An explosion can cause a factory to shut down for months, disrupting the supply chain.

Case: A fire on an offshore drilling platform caused by a faulty non-explosion-proof motor resulted in hundreds of millions of dollars in repair and production losses.

3. Comply with international regulations to avoid legal risks.

Strict global regulation:

EU: ATEX Directive (2014/34/EU) mandates the use of explosion-proof equipment in high-risk areas.

US: NEC (National Electrical Code) 500-506 zone classifications, OSHA regulations.

China: GB 3836-2010 explosion-proof standard, Coal Mine Safety Regulations (AQ standard).

Penalties for violations: Companies that fail to use compliant explosion-proof products may face heavy fines, production suspensions, and even criminal prosecution.

Case: A chemical plant was fined €500,000 and ordered to suspend operations by the EU for using non-certified explosion-proof switches.

Packing and Shipping:

Product Packaging:

The explosion-proof switch is carefully packaged in a sturdy cardboard box to ensure safe transportation. The switch is wrapped in protective materials to prevent any damage during shipping.

Shipping Information:

Once your order is placed, our team will process it quickly and ship the explosion-proof switch to your specified address. We partner with reliable shipping carriers to ensure timely delivery of your product. You will receive a tracking number to monitor the status of your shipment.

FAQ:

Q: What is the brand name of the Explosion Proof Switch?

A: The brand name is CROWN EXTRA.

Q: What is the model number of the Explosion Proof Switch?

A: The model number is ZXF8030.

Q: What certifications does the Explosion Proof Switch have?

A: The Explosion Proof Switch is certified with ATEX, CNEX, ISO, and CE.

Q: What is the minimum order quantity for the Explosion Proof Switch?

A: The minimum order quantity is 10 PCS.

Q: What are the payment terms accepted for purchasing the Explosion Proof Switch?

A: The accepted payment terms are T/T and Western Union.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!